Product details

We supply Ready Mixed Concrete within the Kent and South-East London area, and we continue to be committed to offering quality both in product and customer service.

Our Concrete business can offer an hourly output of over 120m3, utilising our digital production methods at our RMC depots in Darenth & Gravesend, along with our own fleet of dedicated drivers and mixer trucks, it is our aim for a smooth transition of deliveries to site to make your job easier.

We recognise that the delivery service offered to our customers will influence the total cost and experience of purchasing our products, and for this, our local central shipping office is manned by multi-trained experienced personnel who have direct links to all vehicles and plants.

All our vehicles are equipped with GPS Tracking & Navigation which enables us to give you an instant up-date tracking on the progress of your order from dispatch time to delivery time.

A collection service is also offered from our Darenth depot, please note: Minimum P.P.E. requirements must be worn upon collection and collections are only available on a suitable vehicle fitted with a covering sheet.

Standard & Specialist Concrete

Our own in-house laboratory team are constantly monitoring our concrete performance to ensure that target strengths and standards are maintained and our reputation for good quality concrete is upheld by adhering to our BSI Kitemarks and ISO 9001 & ISO 14001 standards.

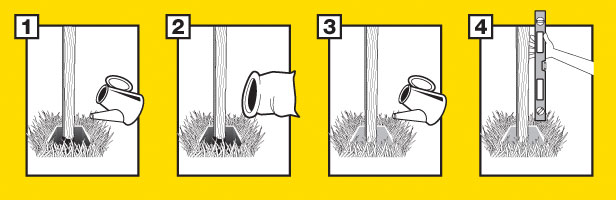

There are plenty of different applications of concrete, it can be used for walls, flooring, foundations, shed bases and many more, but not every concrete mix is the same and depending on the application you need to ensure that you are choosing the correct concrete mix that is fit for purpose.

Concrete mixes can utilise many different materials to give different qualities and strengths, however, generally they will all use cement, water, sand, and aggregate to achieve the desired mix.

In order to provide our customers with a comprehensive service, we can offer the following supplemental services & specialist concretes tailored to your requirements for domestic & commercial purposes.

Admixture Concrete

Admixtures are natural or manufactured chemicals which are added to the concrete during mixing. The most often used admixtures are; super plasticizer, air-entraining agents, water reducers, water-reducing retarders and accelerators and can help with a variety of applications.

Fibre Reinforced Concrete

Fibre-reinforced concrete contains fibrous material which increases its structural integrity. It contains short discrete fibres that are uniformly distributed and randomly oriented, this can save on using steel reinforcement and is ideal for hard wearing floors.

Waterproof Concrete

Impermeable concrete used for long-lasting, durable watertight construction, to improve the impermeability of the concrete, typically used for swimming pools, ponds and reservoirs.

Hot Water Concrete

Added to the mix to help with concrete reaching its strength in cold conditions and prevent it going off too quickly.

Contact Information

We recognise that not every site is the same as the next, and there are always challenges to be met, be it logistics, time constraints, road & site restrictions, the only thing we cannot help with is the Great British weather!

We like to think we can offer a suitable solution to suit every site’s needs.

For more information on our products and services, or to purchase concrete, please contact the Main Office concrete line on 01322 225431 option 3 or email direct to salescc@clubbconcrete.co.uk

any requirements you have, and one of our team will be happy to assist you.